What it takes to build a brand

Pattern creation, material sourcing, wear and wash tests… just some of the things we need to do, to create one of our unique jerseys.

Creating a cycling jersey is a complex process. It takes specialized knowledge and skill to design and manufacture cycling wear. Most private label brands contact manufacturers and have their logo stitched onto a standard jersey, not unlike how cycling clubs would go about ordering their kit. That is of course an option, yet it is not the path we at Maison Poulain chose to ride.

Questions while building a brand

From the moment of inception Maison Poulain strived to be different. We tried to be unique in our approach while being very conscious about every step in the process. Why create another jersey using the same Italian fabrics as everybody else? Why ship clothing all around the globe? How much to produce and what is the price point? How to guarantee fair working conditions? Those were just a couple of the questions that needed answering. Yet there had to be a good reason to start another brand in an already overcrowded market. We found it in our own conscious lifestyle and values. Buy less, buy better, buy fair and with a heart for the environment.

Partners while building a brand

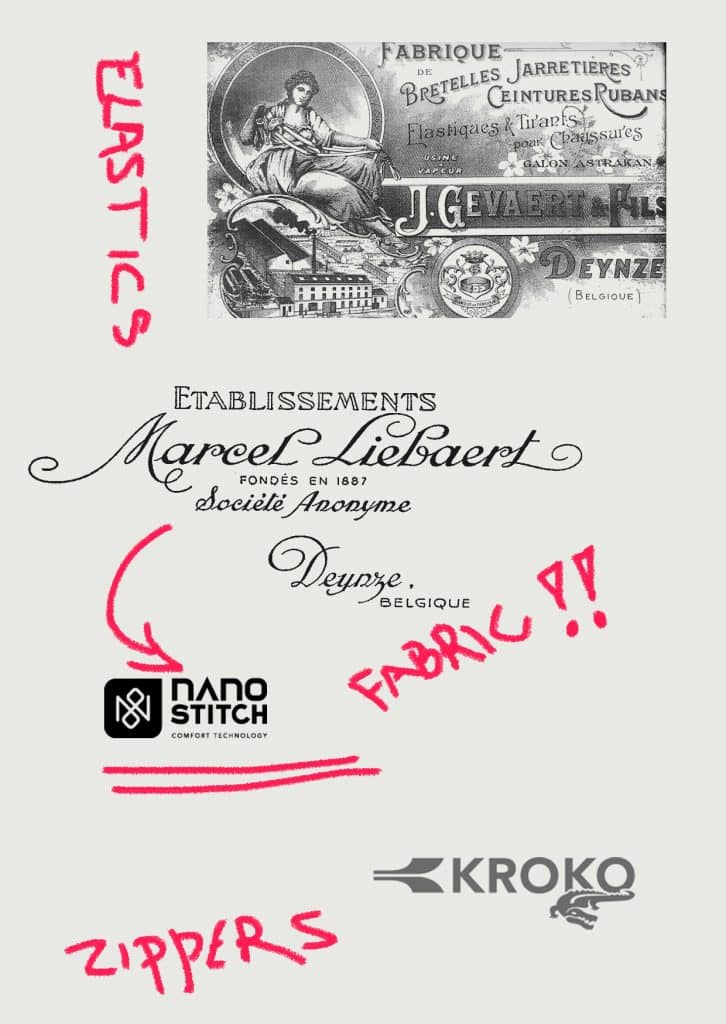

During our journey we were lucky enough to have found local partners and companies that helped us with knowledge and skill, but also shared the same values as we do. Liebaert Textiles has been on board since the very beginning. They manufacture ultra high-quality fabrics in Belgium. Their high tech Nano Stitch range is one of the cornerstones of our brand. The fabrics immediately elevated what would have been a regular cycling jersey to a high tech and luxurious item while remaining true to our values.

Sprinting trough development

Once we locked down our fabric partner we went on and connected with the people at the BioRacer Protolab. They helped us with the wear testing and fit of our Nano Stitch fabrics as they have developed special machines to do so. While sourcing zippers and elastics we ended up at Kroko and Gevaert Bandweverij, two other Belgian companies. In the meantime we had our independent pattern creator working hard on the technical drawings.

Local manufacturing was another hurdle. Studio Ama helped us find the right partner. They connected us to De Posthoorn, an inclusive workplace that helps people with difficulties entering the job market. This made for our local brand to also become a social brand. A million issues and decisions later you end up where we are now with a unique, high-end, local and consciously-made cycling kit.

Why we continue

Claiming to be different is one thing, actually living up to that is another. Even though globalization has brought welfare and affordable products to many, it has also inducted harm to a lot of things. Because we are an independent brand we do not have any investors to answer to except for our clients, the people who ride in MSNPLN, the pioneers, our poulains, YOU. We do not take that trust lightly even though this makes creating cycling wear more difficult and more expensive. We will always choose our values over profit.